Plastic revaluation in sustainable businesses

- Javier Trespalacios

- May 30, 2020

- 12 min read

Updated: Sep 12, 2025

In 2022, global plastic production exceeded 400 million tons, but only 9% was recycled, increasing waste accumulation in landfills and raising greenhouse gas (GHG) emissions (Plastics Europe, 2023; UN, 2022). Beyond the environmental challenge, this gap drives technological innovations and circular business models capable of generating economic value and reducing dependence on fossil raw materials.

Plastic with revaluation (photo by Javier Trespalacios)

Virgin plastic production: processes and emissions

Virgin plastic manufacturing starts with crude oil extraction, which is transformed into naphtha in refineries. Through thermal cracking, naphtha is converted into monomers [1] —such as ethylene and propylene— which are then polymerized, forming long molecular chains. Additives are added to polymers to provide flexibility, resistance, or color, and they are finally distributed as pellets to the manufacturing industry (Plastics Europe, 2019).

Virgin plastic production process

This conventional process has a significant environmental impact. Below is a synthesis of seven [2] of the most used plastics, their common applications, CO₂ emissions associated with production —virgin and recycled—, and global recycling rates:

Plastic Type | Common Uses | Global Production (%) | Virgin CO₂ (kg CO₂e/t) | Recycled CO₂ (kg CO₂e/t) | Savings (%) | Global Recycling Rate (%) | Natural Degradation (years) |

PET | Beverage bottles, containers | 10.8% | 3,500 | 1,300 | 63% | 20% | 450 |

HDPE | Milk containers, detergents | 19.8% | 2,800 | 1,200 | 57% | 14% | 400 |

PP | Pipes, coatings | 5.3% | 2,600 | 1,400 | 46% | 10% | 30 |

LDPE | Bags, plastic film | 13.9% | 2,800 | 1,500 | 46% | 5% | 500 |

PS | Caps, yogurt containers | 5.9% | 3,200 | 2,000 | 38% | 9% | 500 |

PVC | Packaging, disposable cups | 19.1% | 2,900 | 2,000 | 31% | 1% | 150 |

Others | CDs, car parts, bottles | 3.7% | 2,500 | 1,500 | 40% | <1% | Variable (500–1,000 years) |

Source: Adapted from Plastics Europe (2023) and Quantis (2020)

The use of recycled plastic significantly reduces CO₂ emissions: for example, recycled PET emits 1,300 kg CO₂e/t compared to the 3,500 kg CO₂e/t of virgin PET, achieving savings between 31% and 63%. However, global recycling rates are low (from 1% to 20%), and their natural degradation can take from 30 to 1,000 years depending on the type.

Evolution of Plastic Recycling

From the institutionalization of recycling in the seventies —with the installation of the first recyclable materials processing center in Conshohocken, Pennsylvania— to the global expansion of PET and HDPE in the eighties, advances have been notable (Hopewell et al., 2009). However, disparities persist: while countries like Germany, South Korea, and Japan recycle more than 50% of their plastics, many emerging economies recycle less than 10% due to technological limitations and lack of awareness (Plastics Europe, 2023).

Plastic recycling process

The recycling process integrates post-consumer collection, sorting —manual or optical—, cleaning, shredding, reprocessing —thermal or chemical—, and manufacturing of new products. Effectiveness depends on rigorous source separation and thorough washing, challenges that slow industrial expansion (Association of Plastic Recyclers, 2023).

Plastic Type | Recyclability | Recycled Products | Technical Difficulties |

PET | Highly recycled due to demand and ease of reprocessing | Textile fibers, carpets, and new bottles | Cross-contamination affecting quality |

HDPE | High, good rate due to chemical stability | Pipes, furniture, containers | Complex color separation |

PVC | Limited, chlorine, and toxic substance release | Flooring, hoses, profiles | Risk of toxic compound release |

LDPE | Medium, less demanded, recyclable on a smaller scale | Bags, wrappings, flexible pipes | Low demand and contamination with other plastics |

PP | Medium-high, growing recyclability due to technological improvements | Containers, automotive parts, fibers | Difficult separation and cross-contamination |

PS | Limited, uncommon due to low profitability | Frames, insulators, rigid containers | Fragile material; difficult handling |

Others (PC, ABS, etc.) | Variable according to type and available technology | Specific products according to type | High difficulty for classification |

Source: Own elaboration based on Association of Plastic Recyclers (2023) and Al-Salem et al. (2009)

Is plastic recycling profitable?

Recycling PET to produce rPET requires between 1.1 and 1.5 tons of used bottles to obtain one ton of recycled material (OECD, 2018). When large-scale plants, advanced plastic sorting technologies, and high oil prices are not available, rPET is usually more expensive than virgin plastic, especially in the absence of regulatory incentives (World Economic Forum, 2020). In 2019, Coca-Cola European Partners confirmed that producing bottles with rPET was more costly but maintained this practice for environmental and reputational reasons (UNEP, 2018).

According to estimates, PET recycling costs are distributed as follows: transportation accounts for between 15% and 20% of the total; separation and cleaning, between 25% and 30%; and industrial processing, between 20% and 25% (World Economic Forum, 2020; UNEP, 2018).

To address this disadvantage, some governments have implemented economic measures: Canada imposes taxes on virgin plastic; the United States offers tax credits to recyclers; and the European Union sets minimum recycled content quotas in packaging, thus strengthening demand for rPET and reducing its disadvantage compared to new material (OECD, 2020).

A large share of plastics that are not recycled, including many types difficult to process, end up in landfills, incinerated, or polluting ecosystems, highlighting the need to improve management and increase recycling rates (UNEP, 2018; OECD, 2018). astic taxes (Canada), recycling tax credits (USA), and recycled content requirements (EU) are creating more favorable conditions for recycling investments to become sustainable over time (OECD, 2022).

Can recycled plastic pose a health risk?

All plastics, including recycled ones, can release harmful chemicals such as antimony [3] and bisphenol A [4], although recycled materials usually show higher emission levels (Brunel University London, 2021; Plasticsoupfoundation, 2021). In addition, burning plastics in landfills produces toxic compounds such as dioxins [5], furans [6], and fine particles [7], which are associated with lung diseases, cancer, and endocrine [8] disruptions (WHO, 2018; United Nations Environment Programme, 2019). In the case of textiles made from recycled plastic, it has been shown that they release microplastics [9] during use and washing, contributing to environmental pollution and human exposure to these particles (Napper & Thompson, 2016; De Falco et al., 2019). Therefore, although recycling helps reduce waste, it is necessary to consider that all plastics, including recycled ones, can cause harm to health and the environment.

World Recycling Day

Established by UNESCO in 2005, it is observed every May 17th to encourage proper waste management and environmental sustainability, promoting the circular economy and ecosystem protection through reducing, reusing, and recycling materials (Colegio San Juan Bosco, 2020).

World Recycling Day, May 17th (Suforall)

The Commercial and Emotional Value of Recycled Products

Recycled and sustainable products are consolidated as goods with economic, symbolic, and emotional value, representing conscious choices that reinforce consumer identity. Their demand grows, driven by the global trend toward responsible consumption, where more people opt for options with lower environmental impact, even paying a premium (UNEP, 2023). In this context, green marketing [10] becomes a strategic tool for brands, articulating narratives based on transparency, traceability, and environmental commitment. Sustainability stops being an added value to become a central axis of differentiation and competitive positioning in sectors like fashion, food, or technology.

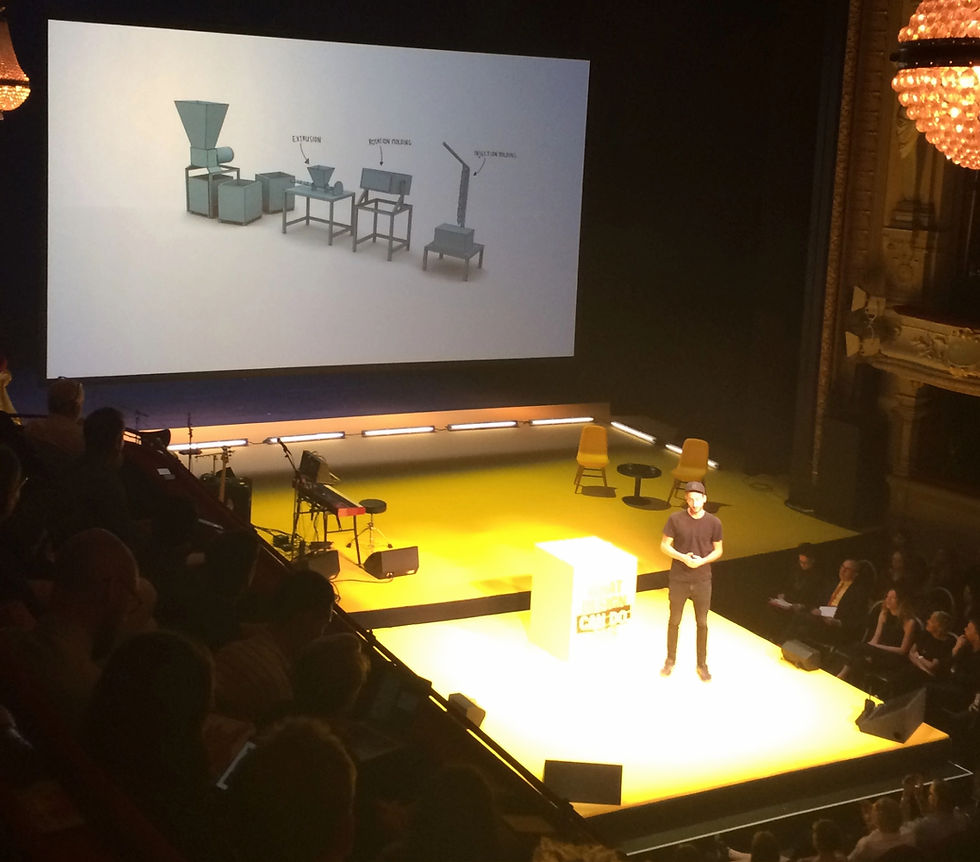

Democratization of Recycling: The Precious Plastic Model

Dave Hakkens [11] launched the open-source Precious Plastic project in 2013, designed to democratize recycling by freely offering blueprints and manuals for four modular machines —shredder, extruder, injector, and press—. These machines can transform plastic waste into flakes, filaments, molded pieces, and compact plates (Precious Plastic, 2022). This decentralized initiative has driven the development of numerous microenterprises in various countries, allowing local communities to transform PET, HDPE, PP, and other plastic waste into utilitarian products without needing complex industrial infrastructure (Kuchta-Helbling, 2018).

Dave Hakkens presenting his open source machines (photo by Javier Trespalacios)

Notable examples of this technology's application include Gjenge Makers in Kenya, which manufactures paving stones from locally collected plastic, and Plastika in Mexico, which uses recycled HDPE and PP to produce domestic furniture. In Indonesia, initiatives like Bali Recycling have integrated these technologies into employment and environmental education programs, producing both fashion accessories and construction materials.

Video of Dave Hakkens' open source machines

Sustainable business models with recycled plastic

The plastic recycling field encompasses various business opportunities, each leveraging specific properties of different post-consumer polymers. Entrepreneurship categories by sector:

Sustainable fashion

Ecoalf uses recycled PET, reducing water consumption by 40% (Ellen MacArthur Foundation, 2022).

Ecoalf clothing with recycled plastic

Construction materials

ByFusion (USA) produces mixed plastic bricks —a mixture of different plastic types— with 30% less carbon footprint (Ellen MacArthur Foundation, 2016).

ByFusion, recycled plastic bricks

Sustainable packaging

Vegware uses recycled PET in its packaging, which has allowed it to reduce its carbon footprint and improve its brand image, strengthening its commitment to sustainability.

Furniture and design

The New Raw (Netherlands) reuses recycled HDPE and PP to manufacture urban and domestic furniture through 3D printing and traditional molding, achieving durable pieces, weather-resistant, and with high aesthetic value (Precious Plastic, 2022).

Sports and recreation

Bureo (USA/Chile) transforms abandoned fishing nets, one of the most harmful plastics for oceans, into products like skateboards, sunglasses, and sports accessories, combining environmental mitigation with added value for conscious consumers (Bureo, 2020).

Guide to Starting a Recycled Plastic Business

To venture into this sector, there are key aspects to consider to maximize success probabilities:

Local waste flow analysis: Identify availability and typology of plastics in the region —PET, HDPE, PP, etc.— to choose the most suitable process and product (Association of Plastic Recyclers, 2023).

Investment in purification and sorting technologies: Adopting effective washing systems and advanced sorting (such as NIR [12] technologies) ensures obtaining consistent quality raw materials and improves recycling process performance (Faraca & Astrup, 2019).

Establishing strategic alliances: Collaboration with municipalities, environmental organizations, and open-source platforms like Precious Plastic allows sharing knowledge, reducing research and development costs, and fostering community adoption of the business (Precious Plastic, 2022).

Obtaining certifications and labeling: Acquiring recognized ecological seals (such as Ecolabel or ISO 14021 compliance) endorses recycled content and product sustainability, generating consumer confidence and market differentiation (ISO, 2016).

Developing a clear value proposition: Define competitive advantages —such as mechanical resistance, innovative design, or reduced environmental footprint— and build an authentic brand narrative that communicates the business's positive impact, avoiding "greenwashing" [13] practices (Ellen MacArthur Foundation, 2016).

Plastic recycling's contribution to Sustainable Development Goals

Plastic recycling constitutes an effective mechanism for achieving multiple Sustainable Development Goals established in the United Nations' 2030 Agenda:

SDG 8 "Decent Work and Economic Growth": UNEP, 2021, has documented how inclusive recycling businesses in emerging economies generate green jobs for vulnerable populations.

SDG 9 "Industry, Innovation and Infrastructure": Initiatives like Precious Plastic foster the development of sustainable and accessible technologies in resource-limited contexts.

SDG 12 "Responsible Production and Consumption": Represents the most evident connection, promoting waste reduction through prevention, reduction, recycling, and reuse (Ellen MacArthur Foundation, 2022).

SDG 13 "Climate Action": Implementing circular practices in the plastics sector could reduce greenhouse gas emissions by 25 million tons annually by 2040, contributing significantly to climate change mitigation (World Economic Forum, 2021).

SDG 14 "Life Below Water": Recycling directly contributes to reducing plastic pollution in oceans, thus protecting marine biodiversity and coastal ecosystems.

SDGs 8, 9, 12, 13, 14 (United Nations)

Conclusion

The future of plastic is not in prohibiting it nor using it without control, but in responsibly integrating it into circular systems where it retains its value for as long as possible. The valorization of plastic waste, supported by science, technology, and design, not only reduces environmental impacts: it also drives economic and social benefits. Today, entrepreneurs, engineers, designers, and consumers have the opportunity to rewrite this material's history, transforming it from a symbol of pollution into a driver of sustainability.

I have always compared a steel bar with a PET bottle: both are valuable resources, not waste... JT

*****

Annexes

Resources for creating recycled product companies:

Precious Plastic Community: Global platform offering recycling machine blueprints, technical discussion forums, and a marketplace to connect with other entrepreneurs. Includes step-by-step guides to start different types of recycling businesses adaptable to various socioeconomic contexts.

Ellen MacArthur Foundation - New Plastics Economy: Resources on circular business models with detailed case studies, product design tools, and strategies to optimize value chains in the circular economy applied to plastics.

Global Alliance for Incinerator Alternatives (GAIA) - Zero Waste Business Toolkit: et of practical tools to develop zero-waste businesses, including financial models, legal aspects, and communication strategies specific to recycling ventures.

Notes

[1] Monomers are small molecules that can join together to form larger structures called polymers. This joining process is known as polymerization. Monomers are fundamental in chemistry and industry, as materials like plastics, synthetic fibers, and resins are created from them. A common example of a monomer is ethylene, used to produce polyethylene, one of the world's most used plastics.

[2] The most common plastics are identified by acronyms representing their chemical composition. PET —Polyethylene Terephthalate— is widely used in beverage bottles and food containers for its resistance and transparency. HDPE —High-Density Polyethylene— is a rigid and durable polymer used in cleaning product containers and pipes. PVC —Polyvinyl Chloride— stands out for its versatility, used in construction —windows, pipes— and medical applications. LDPE —Low-Density Polyethylene— is more flexible and used in plastic bags and wrappings. PP —Polypropylene— is heat-resistant, making it ideal for reusable containers, straws, and automotive components. PS —Polystyrene—, known for its rigidity and insulation capacity, is commonly found in disposable cups and packaging. Finally, the "Others" category includes plastics like PC —Polycarbonate—, which is transparent and impact-resistant, used in compact discs and electronic equipment, and ABS —Acrylonitrile Butadiene Styrene—, a resistant plastic used in appliance casings, toys, and car parts.

[3] Antimony: Metal used in the manufacture of some plastics and as a flame retardant in textiles; it can be released during industrial processes.

[4] Bisphenol A: Chemical compound used in plastics and resins, linked to potential effects on human health, especially at high doses.

[5] Dioxins: Highly toxic and persistent chemical compounds, mainly generated during combustion processes and in certain industries.

[6] Furans: Compounds similar to dioxins, also toxic and persistent, are produced during the combustion of materials such as plastic.

[7] Fine particles: Small solid or liquid fragments less than 2.5 micrometers in size, generated during the burning of plastics, which can penetrate deep into the lungs and affect respiratory and cardiovascular health.

[8] Endocrine disruptions: Changes in the hormonal system caused by exposure to certain chemicals, which can alter growth, development, and reproduction.

[9] Microplastics: Small pieces of plastic less than 5 millimeters in size, present in the air, water, and soil, resulting from the fragmentation of plastic waste and which can be ingested by animals and humans, accumulating in the environment and the food chain.

[10] Green marketing is a strategy that highlights the ecological qualities of products or services to attract environmentally conscious consumers.

[11] Dave Hakkens is a Dutch designer focused on sustainability and open-source design. He has created projects like Precious Plastic, a global network promoting recycling through accessible machines; Phonebloks, a modular phone concept to reduce electronic waste; and Project Kamp, a self-sufficient community exploring sustainable ways of living. He also promoted Story Hopper, to share ideas that inspire solutions, and Fixing Fashion, which encourages clothing repair. These initiatives are integrated into One Army, his platform to address environmental problems through collective action.

[12] In the recycling context, for example, NIR technologies are used to identify and classify different plastic types by detecting their spectral signature, allowing more precise and efficient material separation. This improves recycled material quality and reduces cross-contamination between polymers.

[13] The goal of greenwashing is to improve public image or attract environmentally conscious consumers, but it can mislead and make informed decision-making difficult. Common examples include vague labels like "eco-friendly" without certification, using green colors and natural symbols for polluting products, or exaggerating the environmental benefits of minor actions.

Bibliographic References

Al-Salem, S. M., Lettieri, P., & Baeyens, J. (2009). Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Management, 29(10), 2625–2643. https://doi.org/10.1016/j.wasman.2009.06.004

Association of Plastic Recyclers. (2023). The plastic recycling process. https://plasticsrecycling.org/how-recycling-works/the-plastic-recycling-process

Brooks, A. L., Wang, S., & Jambeck, J. R. (2018). The Chinese import ban and its impact on the global plastic waste trade. Science Advances, 4(6), eaat0131. https://doi.org/10.1126/sciadv.aat0131

Brunel University London. (2021). Chemicals in recycled plastic food packaging. (Cited in: Plasticsoupfoundation, 2021, March 1). https://www.plasticsoupfoundation.org/blog/recycled-pet-plastic-is-not-a-safe-packaging-material-for-food-and-drink/

Bureo. (2020). Our products. https://bureo.co/pages/products

Ehrenstein, G. W., Riedel, G., & Trawiel, P. (2019). Plastics handbook: The ABC's of plastics. Carl Hanser Verlag GmbH & Co. KG.

San Juan Bosco School. (2020, May 15). World Recycling Day: May 17. https://sanjuanboscosalamanca.salesianas.org/dia-mundial-del-reciclaje-17-de-mayo/

De Falco, F., Gullo, M. P., Gentile, G., Di Pace, E., Cocca, M., Gelabert, L., ... & Avella, M. (2019). Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environmental Pollution, 236, 916-925. https://doi.org/10.1016/j.envpol.2018.10.006

Ellen MacArthur Foundation. (2016). The new plastics economy: Rethinking the future of plastics & catalysing action. https://ellenmacarthurfoundation.org/our-work/activities/new-plastics-economy

Ellen MacArthur Foundation. (2022). The Global Commitment 2022 Progress Report. https://ellenmacarthurfoundation.org/global-commitment/2022-progress-report

Faraca, G., & Astrup, T. (2019). Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Management, 95, 388–398. https://doi.org/10.1016/j.wasman.2019.06.007

Hopewell, J., Dvorak, R., & Kosior, E. (2009). Plastics recycling: Challenges and opportunities. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 2115–2126. https://doi.org/10.1098/rstb.2008.0311

International Labour Organization [ILO]. (2021). Green jobs in waste management. https://www.ilo.org/global/topics/green-jobs/publications/WCMS_823122/lang--en/index.htm

ISO. (2016). ISO 14021: Environmental labels and declarations—Self-declared environmental claims (Type II environmental labelling). International Organization for Standardization.

Kuchta-Helbling, A. (2018). How Precious Plastic is transforming communities worldwide.

United Nations. (2022). The Sustainable Development Goals Report 2022. United Nations.

Napper, I. E., & Thompson, R. C. (2016). Release of synthetic microplastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Marine Pollution Bulletin, 112(1-2), 39-45. https://doi.org/10.1016/j.marpolbul.2016.09.025

Plastics Europe. (2019). Plastics – the Facts 2019: An analysis of European plastics production, demand and waste data. Plastics Europe.

Plastics Europe. (2023). Plastics – the Facts 2023. https://plasticseurope.org/knowledge-hub/plastics-the-facts-2023/

OECD. (2018). Improving Markets for Recycled Plastics: Trends, Prospects and Policy Responses. OECD Publishing. https://www.oecd.org/environment/improving-markets-for-recycled-plastics-9789264301017-en.htm

OECD. (2020). The Economic Case for Recycling Plastics. OECD Environment Policy Paper No. 18. https://www.oecd.org/environment/the-economic-case-for-recycling-plastics-92c07b70-en.htm

OECD. (2022). Global Plastics Outlook: Policy Scenarios to 2060. https://www.oecd.org/environment/global-plastics-outlook-policy-scenarios-to-2060-f065ef59-en.htm

Precious Plastic. (2022). Impact Report 2021-2022. Precious Plastic Foundation.

United Nations Environment Programme [UNEP]. (2021). Turning the tide: How to finance a sustainable ocean recovery. UN Environment Programme.

Quantis. (2020). Climate tech guide: Carbon footprint of recycled plastics. https://quantis.com/report/climate-tech-guide-plastics

Thompson, R. C., Moore, C. J., vom Saal, F. S., & Swan, S. H. (2009). Plastics, the environment and human health: Current consensus and future trends. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 2153–2166. https://doi.org/10.1098/rstb.2009.0053

United Nations Environment Programme (UNEP). (2023). Sustainability and Circularity in the Global Economy. Nairobi: UNEP. https://www.unep.org/resources/sustainability-and-circularity-global-economy

UNEP. (2018). Single-Use Plastics: A Roadmap for Sustainability. United Nations Environment Programme. https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability

Vilaplana, F., & Karlsson, S. (2008). Quality concepts in plastics recycling. Waste Management, 28(1), 221-231. https://doi.org/10.1016/j.wasman.2006.11.012

World Economic Forum. (2020). Plastics, the Circular Economy and Global Trade. https://www3.weforum.org/docs/WEF_Plastics_the_Circular_Economy_and_Global_Trade_2020.pdf

World Health Organization (WHO). (2018). Dioxins and their effects on human health. https://www.who.int/news-room/fact-sheets/detail/dioxins-and-their-effects-on-human-health

United Nations Environment Programme (UNEP). (2019). Plastic waste and its management. https://www.unep.org/resources/report/plastics-waste-and-its-management

Bonus track

Dave Hakkens

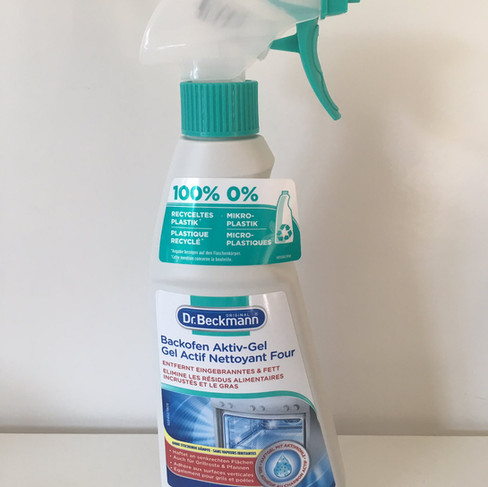

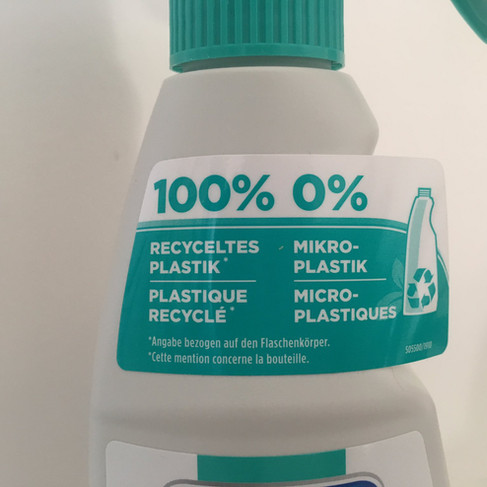

Container in 100% recycled material

Comments